Rock engineering technology has its origins in the mining industry but, over time, methods, equipment and materials have been adapted to meet the needs of the construction industry. Civilian and military underground construction, particularly in cities, grew in the 1940s and 1950s, so manufacturers adapted their product development to the needs of this market.

Rock construction has developed into a comprehensive industrial process, and a strong domestic manufacturing sector has played an important role in this development. Major companies such as Atlas Copco, Sandvik, Nitro Nobel and Volvo have developed drilling machines with drill bars and rods with sophisticated cemented carbide cutting tools, blasting equipment, machines for rock reinforcement, and transport equipment for loading and removing rock spoil.

Project phases

An underground construction project can generally be divided into five phases. From the first phase starting with first assessments of functions, environmental data, initial geological and hydrogeological assessments and physical outline of the project and finally the operational phase after commissioning and maintenance and repair.

-

-

Feasibility study

-

Preliminary design

-

Detailed design

-

Construction

-

Operation

-

Rock excavation

In Sweden, drill-and-blast is the traditional and most commonly used method of building tunnels with a cross-sectional area of up to 100 m2. In recent years, new construction methods have been developed, such as full-face drilling and wire cutting, which can be more suitable in certain situations.

Drill-and-blast: tunnels

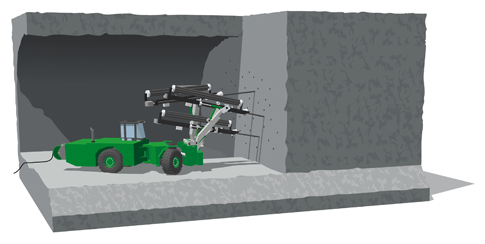

Drill-and-blast comprises a cyclical repetition of activities, where each activity involves the use of special equipment. Rock excavation is an industrial process in which the individual phases are optimised and coordinated. Wherever possible, the work is carried out in parallel on more than one front, and the respective cycle on each front is adapted so that staff and machines can switch between workplaces.

Each round of blasting advances the tunnel face.

Blasting Cycle

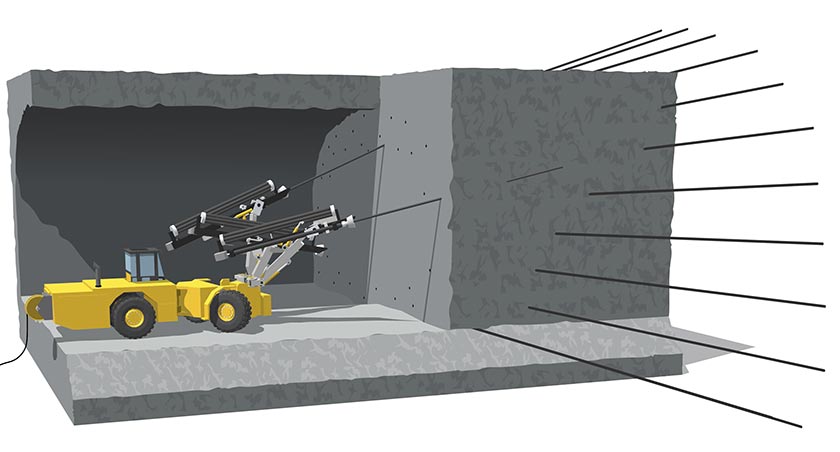

- Blast holes are drilled in a pre-determined pattern

- The holes are filled with explosives and ignition charges

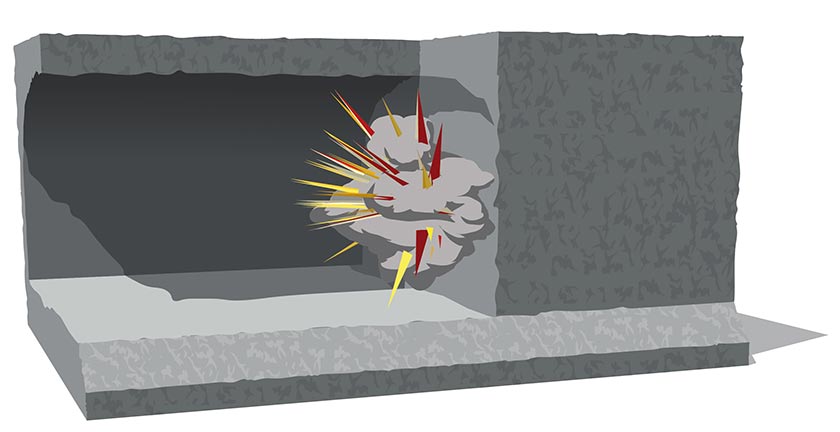

- Detonation shatters the rock

- Loosened and remaining rock from the roof and walls is removed (scaling)

- Rock spoil is loaded onto lorries and transported away

- Roof and walls are reinforced

- The next series of blast holes are drilled

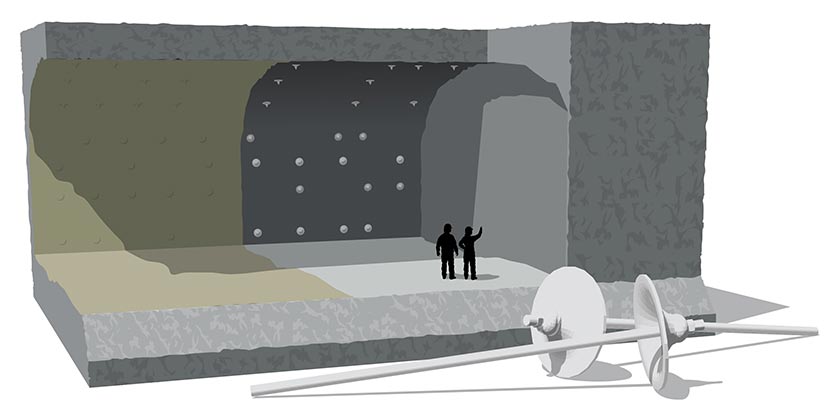

Drill-and-blast: rock caverns

In good-quality rock, the cross-sectional area of rock caverns can be 600 m2 or more. Sloping tunnels (ramps) are first excavated to reach the different levels in the rock cavern, and then cross tunnels are cut into each level. A pilot tunnel is excavated near the top of the planned cavern, and blasting from this side bench removes the rest of the rock in the upper part.

The underlying benches are then blasted. Bench blasting involves blasting in vertical or horizontal holes, drilled in one or more rows against the rock face.

Tunnelling in sensitive urban environments

When tunnels and rock caverns are to be built in urban environments, excavation methods with little or no vibration may be needed. Examples of such methods are diamond wire cutting, hydraulic breakers, hydraulic fracturing, expansion chemicals, and water cutting.

Rock reinforcement

One of the most common reinforcement methods for rock walls and roof is to spray cement on the rock surface using compressed air. The high speed of application produces a layer of very high-quality concrete that often reinforced with fibres.

Bolt reinforcement is used as a separate method or in combination with shotcrete, e.g. bolts anchored in the bottom of the hole or completely cast into rock.

Shotcrete (spray concrete)

Shotcrete can be sprayed dry or wet. In dry spraying, dry cement is delivered by hose to the spray nozzle, where water is added. This provides reinforcement very rapidly, and is suitable for reinforcement measures when the facility is already operational and when the geometry of the tunnel or cavern reduces accessibility.

In wet spraying, ready-mixed cement is pumped through hoses to the nozzle, where compressed air is added. The method provides higher capacity than dry spraying, and thicker layers can be applied. Additives ensure that the quality and hardness of the concrete is comparable with dry spraying. The work environment during wet spraying is more favourable, and there is considerably less material waste. In new production of tunnels and rock caverns, robots are used almost exclusively to spray wet concrete.

By reinforcing shotcrete with fibre, the reinforcement can be created in a single process. In wet spraying, the fibres are added directly in the mixer. The most common type of fibre is made of steel, but plastic fibres are also used.

Bolting

Fixing anchor bolts into rock is simple and relatively cheap. Rock bolts cast in situ in wet concrete before it sets are rustproof and suitable as permanent reinforcement. The bolt usually comprises a cut corrugated bar, and is often fitted with a plate. A pre-stressed rock bolt is anchored in the bottom of the borehole, and is tightened with a nut and washer at the top end. The bolt can be anchored in the bore hole with wedge anchors or expanders.

Pre-stressed bolts can be fitted quickly and provide immediate support, which is valuable in operational reinforcement. However, as bearing capacity and strength are uncertain over time, these bolts are not suitable for permanent reinforcement.

Friction bolts work as a combination of anchor and pre-stressed bolts. The most common types comprise folded steel tubes or tubes with a slot along their length that are hammered in, creating friction against the inside of the borehole and providing rapid operational reinforcement. Friction bolts are not used for permanent reinforcement.

Grouting

Tunnels and rock caverns must be sealed against inflow of groundwater. This is particularly important in urban areas if the buildings above the facility have foundations in clay. A lowering of the groundwater pressure in clay may cause subsidence, damaging foundations and degrading wooden piles and support structures.

Grouting

Cement with different grain sizes is usually used for sealing rock. The most common type is Portland cement, which is finely ground to increase its penetration into small cracks.

Chemical grouts have very high penetrability. Most of them harden in contact with water and seal the rock very rapidly and effectively. The spread of these types of grout must be carefully monitored, and applied quantities should be limited.

Grouting of tunnels and rock caverns is usually divided into two main types:

Pre-grouting means that the rock is sealed before the tunnel is blasted. Grouting can then be applied in a controlled way at high pressure, making it effective.

Post-grouting is carried out when groundwater flows in after the tunnel has been blasted, and is a complicated and costly procedure.

Other factors, such as work environment, pumping costs, whether the rock can be reinforced with rock bolts and shotcrete, and the function of the finished facility, can make it important to limit the inflow of water. Maintenance of the facility is also highly dependent on how much groundwater flows in.

Rock Transport

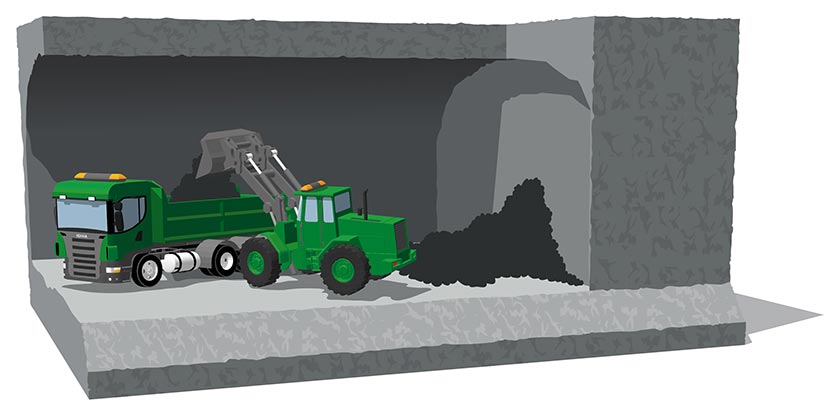

The most common loading machines in underground constructions are diesel-driven wheel loaders (see diagram). Such machines can be used as a ‘dig-and-carry’ machine over small transport distances.

Rock spoil is normally removed on ordinary lorries or dumper trucks, operating in the service tunnel.

Disruptions to surroundings

When a rock facility is being built, disruption and inconvenience to the surroundings is unavoidable. Examples are noise and dust from drilling, vibrations, and shock waves from blasting. Transport of rock spoil is often perceived as disruptive, not least if the rock is being transported through residential areas; this is the case in many underground projects in urban areas.

The issue of disturbance to the surroundings must be addressed in various ways during planning. The size of detonations can be adapted to the surroundings, a measurement programme for vibrations can minimise damage, and blasting can be restricted to acceptable times of the day.

By using careful blasting methods, vibrations and disturbance to the surroundings can be radically reduced. Interval blasting with weak charges in contour holes is one such method.

Completion and fittings

Tunnels and rock caverns are fitted with installations and furnishings appropriate for the intended use. These can be anything from a hydraulically designed concrete base that facilitates transport of water to buildings inside the rock cavern to artistic decoration in road tunnels to create an interesting scenery and add a positive experience and help motorists orientate themselves.